Triplex

|

Maximum dimensions |

2300 х 1300 mm |

|

Minimum dimensions |

100 х 100 mm |

| Minimum thickness of the finished product | from 8 mm |

Our company's specialists are ready to provide information on issues related to production, technical parameters, terms of manufacturing and delivering glass and mirror products, as well as on other interesting you issues!

Triplex (from Lat. triplex - triple) - laminated glass (two or more glasses glued together with a special polymer film or a photo-cured composition capable of holding fragments on impact).

Triplex glass is made using the technology of gluing several sheets. Moreover, they can be both raw and tempered. When using the latter, technical and operational characteristics are increased to the maximum level.

The strength of the triplex depends on the type of glued sheets. The material consisting of raw glasses withstands shocks much better than usual analogues. At the same time, the triplex does not crumble into fragments when damaged. They are securely held with a film.

The finished triplex glass is subjected to tests and inspections, including testing of glass for resistance to impact, penetration, light, humidity and heat, incandescence, heat shock, resistance to disintegration into fragments.

Main advantages

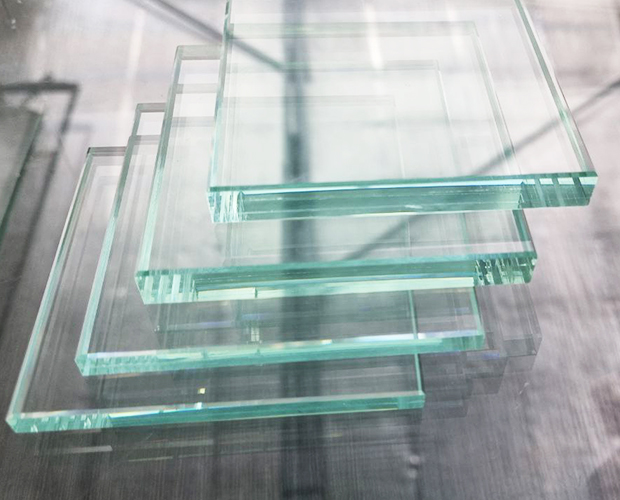

Samples of our glassware

Areas of application of triplex glass:

-

in the design of entrances and lobbies of public buildings;

-

creating office partitions and storefronts;

-

glazing stairs;

-

in double-glazed windows installed on the roofs of buildings;

-

glazing trade pavilions and bus shelters;

-

in the manufacture of glass steps;

-

in the manufacture of glass floors.

Stages of work