Cutting

|

The maximum size of the glass sheet |

6000 х 3210 mm |

|

Minimum cut-out mating radius R |

20 |

| Glass thickness | from 3 to 19 mm |

Our company's specialists are ready to provide information on issues related to production, technical parameters, terms of manufacturing and delivering glass and mirror products, as well as on other interesting you issues!

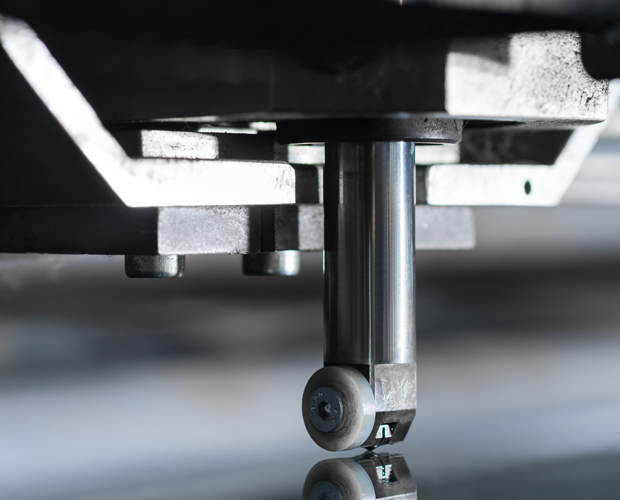

A high-quality defect-free edge is one of the main factors in maintaining the strength of glass during its processing and operation.

Ensuring the high quality of the cut while observing the accuracy of the specified parameters allows to manufacture glass products of almost any complexity just on time.

Main advantages

Here you can observe the operation of our equipment in the process of creating your product

Any production begins with a high-quality defect-free cutting of the glass. During the cutting process, defects are formed on the edge of the glass in larger or smaller quantities, leading to the following hazards:

-

destruction of glass during heat treatment (tempering or bending);

-

increased risk of spontaneous destruction of glass due to thermal shock;

-

increased risk of glass destruction under operational loads: wind and snow loads, own weight, etc.

The use of high-tech equipment and automated programs for accounting and cutting glass in our production allows us to optimize cutting, and significantly reduce costs and waste, which leads to a reduction of glassware the cost and allows us to offer customers the best prices for our products.