Edging

|

The maximum thickness of the glass during processing |

19 mm |

|

The minimum thickness of the glass during processing |

3 mm |

|

The work accuracy |

± 1 mm |

Our company's specialists are ready to provide information on issues related to production, technical parameters, terms of manufacturing and delivering glass and mirror products, as well as on other interesting you issues!

Edge processing is carried out to make the sharp part of the glass and mirror safe and give them a certain shape. The edge of glass products is processed on vertical conveyor machines with high productivity and CNC machines.

Edge processing can be carried out both on straight and figured products made of mirrors and glass of various thicknesses (from 3 to 19 mm) and colors.

Edge processing allows to

Here you can observe the operation of our equipment in the process of creating your product

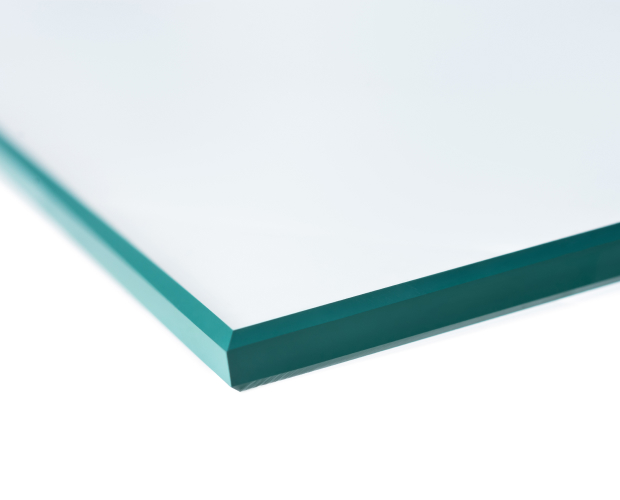

The processed edge can be:

-

mat - processing of the edge with diamond-coated grinding wheels, as a result of which the edge of the glassware becomes matte;

-

polished - represents sequentially: grinding and processing of the edge with polishing wheels at high speeds, the edge becomes transparent.

The processed edge of the glassware has the shape of a:

-

"Trapezoid", which provides the best geometry of straight sections of processing;

-

"Pencil" - the edge of the glass in the form of a semicircle.